The Backbone of Modern Vehicle Communication

What is CAN Bus?

Key Features of CAN

- Single wire CAN – primarily found in specialty automotive applications and emphasizes low cost. Defined in the SAE 2411 specification, single wire CAN uses only one single-ended CAN data wire, as opposed to the differential CAN wires found in most applications.

- Two-wire system (CAN_H and CAN_L) – uses differential signaling for noise immunity

- Broadcast communication – one node sends, many can listen

- Prioritized messaging – ID-based arbitration ensures important messages get through

- Error detection & handling – CRCs, ACKs, and fail-safe features

- Speed – typically up to 1 Mbps (or 8 Mbps with CAN FD)

How CAN Messages Work

A CAN message isn’t like an email with a “to” and “from”—instead, every message has an identifier (ID) that signifies what kind of data it contains (e.g., “engine RPM” or “brake status”). Any ECU that’s interested in that kind of message simply listens for it.

Each message contains:

- ID (11 or 29 bits)

- Data Length (0–8 bytes for CAN 2.0, up to 64 for CAN FD)

- Data Payload

- CRC & error bits

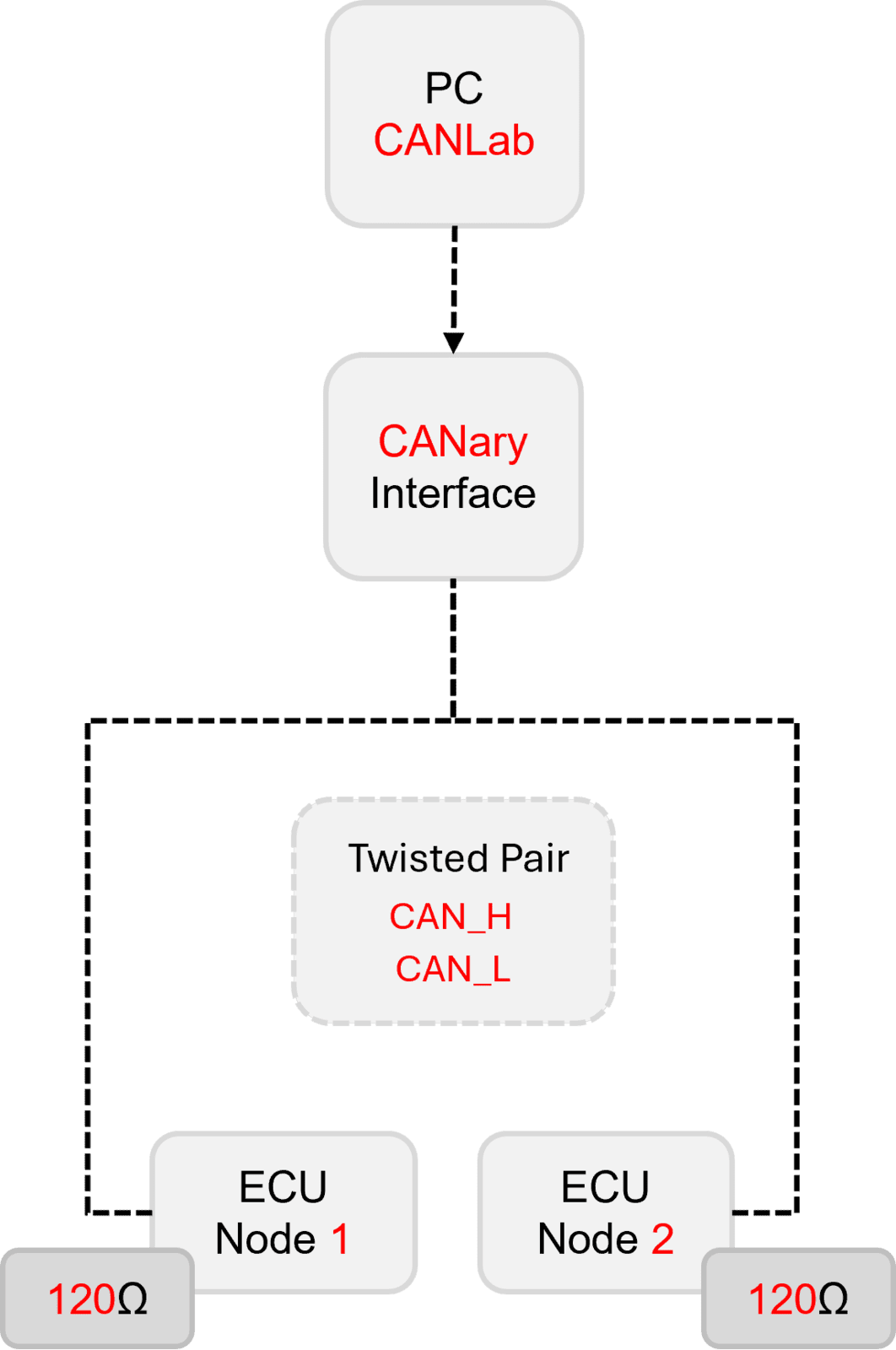

What You Need to Get Started

- A CAN interface – to connect your PC to a CAN network

- Software – to monitor, log, and send messages

- A target network – either a simulator, bench ECU, or development board

- Plug-and-play

- Supports standard CAN and CAN FD (with CANary FD)

- Lightweight and portable

- Live message monitoring

- Custom message filtering

- Logging and replaying real-world CAN data

- Learning through scripting and automation (more on that in future blogs!)

Then you need your DBC file. What’s that?

A DBC (Database CAN) file is a plain-text specification that describes how raw CAN frames on a bus map to meaningful, human-readable signals.

| Element | What it defines |

| Messages | Each CAN ID (identifier) that appears on the bus—along with its payload length (0-8 bytes for Classic CAN). |

| Signals | Bit-level slices within the message payload that represent individual data items (e.g., engine RPM, steering-angle). A signal entry specifies: start bit, length, byte order, signed/unsigned, scaling factor, offset, physical units, and value ranges. |

| Nodes | Which electronic control unit (ECU) transmits or receives each message. |

| Additional metadata | Comments, value tables (enumerations), multiplexing rules, diagnostic info, etc. |

How it is used when you “connect” to a vehicle CAN network

- Physical interface & bus parameters

You plug a CAN interface (EG CANary) into the vehicle’s diagnostic connector (OBD-II, J1962) or directly onto a harness breakout. Set the bus speed (e.g., 500 kbit/s) and, if applicable, CAN FD data-rate. - Load the DBC into your tool or code

• CAN analyzers EG ATI’s CANlab parse the DBC.

• The tool now “knows” how to decode each CAN ID. - Live decoding / logging

As frames stream in, the software matches the ID to a message definition in the DBC, extracts signal bits, applies scaling × factor + offset, and presents real-world values (e.g., RPM = 2560 rev/min instead of “0x0A00”). - Transmission / simulation

Conversely, you can compose frames by assigning signal values (e.g., set “CruiseControlSwitch = ON”); the tool packs the bits per the DBC and sends the correctly formatted frame onto the bus. This is essential for HIL/ECU simulation, test benches, or reverse-engineering. - Maintainability & collaboration

Because the mapping is externalized in the DBC, engineers can share, version-control, and update signal definitions without changing the decoding code itself.

In short: A DBC file is your translation dictionary between raw CAN frames and meaningful engineering signals, enabling any compliant software or script to monitor, log, analyze, or inject data on a vehicle CAN network with minimal manual bit-twiddling.

What’s Next?

Now that you know the basics of what CAN is, how it’s decoded with a DBC file and what tools you need to get started, the next blog will walk you through setting up your first CAN network with real tools, proper termination, and message tracing.