Industries We Serve

In an ever-evolving, technologically advanced world, high-speed data collection, precise calibration, ECU rapid prototyping, and model-in-the-loop simulations are a necessity while developing new products or updating existing products in every industry. High-speed data acquisition provides users with measurements of real-world physical conditions from a variety of sensor types, in real-time. Calibration is the method of optimally tuning control algorithms for applications ranging from combustion engines in commercial and industrial vehicles, to generators, or the brake controller on an aircraft.

Automotive ECU and Powertrain

ATI’s product range embraces hardware, software and associated 3rd party products that are designed to maximize productivity, efficiency and development ECUs and / or powertrain development. ATI specializes in a wide range automotive development tool such as ECU Interfaces, DAQ & I/O Hardware, Test Cell, and Software for Calibration/Data Acquisition, ECU Rapid Control Prototyping and CAN bus communication. Thousands of variables are now provided for the engineer to modify and fine tuning them is as complicated as it is critical. ATI tools significantly impact the efficiency and effectiveness of the development process by allowing engineers to measure and time-align relationships of inputs and outputs and make real-time modifications.

Agricultural

A prime example of ATI’s versatility is in the agriculture sector. The accuracy of planting has been drastically improved with the help of VISION Calibration and Data Acquisition software as well as No-Hooks and OnTarget Rapid Prototyping. ATI has partnered to offer calibration for the camera that automates the planting process. Now things such as seed depth, soil density around the seeds and seed to soil contact are predetermined to ensure a higher yield.

Aviation

ECUs control components in aircraft engines such as direct drive, spark ignition and air assist electronic fuel injection and electronically controlled throttle which require precise calibration to produce peak performance and efficiency. VISION is a fully integrated calibration and data acquisition tool that collates signals from ECUs and external sources and allows for real-time calibration and modification of closed loop control systems making it a perfect solution for aircraft, helicopters and drone engines.

Medical

Advancements in medicine have occurred at a rapid rate due to the assistance of new technology. Precision instruments have created new methods for minimally invasive surgery’s providing better care for patients. ATI provides CAN Interfaces to aid in the development of surgical robotics meeting the strict certifications required for medical research and development. ATI and Kvaser partnered solutions are trusted to provide data exchange between the robotics control units and the PC’s ensuring fast and precise data collection in situations with zero room for error.

Heavy Truck and Bus

A common application used on heavy duty construction equipment and large vehicles is connecting a joystick to the ECU over CAN. In this example the operator would control their equipment utilizing the joystick to control components such as a front-end loader or the boom, dipper and bucket on an excavator. Both VISION and CANLab have been utilized for capturing CAN data that the joystick outputs. Additionally, calibration of the joystick movements to the ECU can occur in VISION.

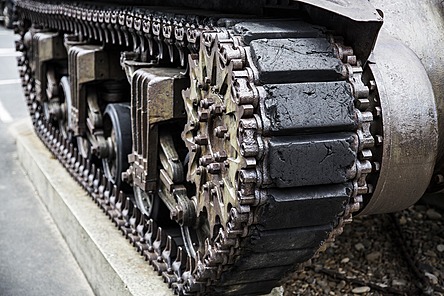

Defense

CAN communication has become a standard across many industries allowing communication between devices and microcontrollers. The defense industry utilizes CAN in vehicles ranging from land combat, transportation and amphibious vehicles. ATI’s CANary provides CAN and CAN FD communication between data acquisition hardware, ECU’s (using CCP or XCP), or other CAN devices compatible with VISION. CANary’s new J2534/2-2019 API allows usage of multiple CAN channels with 3rd party software applications and maintains support for the GMW17753 method.

Marine

Marine engines log countless hours of durability testing during their validation process. ATI provides proven reliable data acquisition via the EMX to ensure secure data capture during testing. The EMX’s modular based design offers a combination of I/O modules to support different applications which provides cost-effective flexibility and efficiency. VISION offers plug and play connectivity with the EMX via ethernet or CAN/CAN FD while providing real-time calibration and modification of the ECU.

Recreational Vehicles

ATI test cell measurement equipment brings a diverse portfolio of ATI hardware as well as 3rd party solutions such as the SmartTach Module, Misfire Generator, Turbo Speed Sensors, CANWAY Current Clamps and Klaric High Voltage Measurement Solutions. Motorcycles, ATV’s, UTV’s and Side by Sides are powered both combustion engines with and without forced inductions as well as all electric motors. ATI offers a complete solution of products with plug and play ease and seamless communication ensuring testing facilities precision and user-friendly measurement equipment.

Other

Universal products such as the CANary Interface module and DLX Datalogger provide CAN communication and data acquisition effortlessly. Paired with VISION Calibration and Data Acquisition software has helped diesel generators optimize their calibrations for performance as well as reductions in emissions.