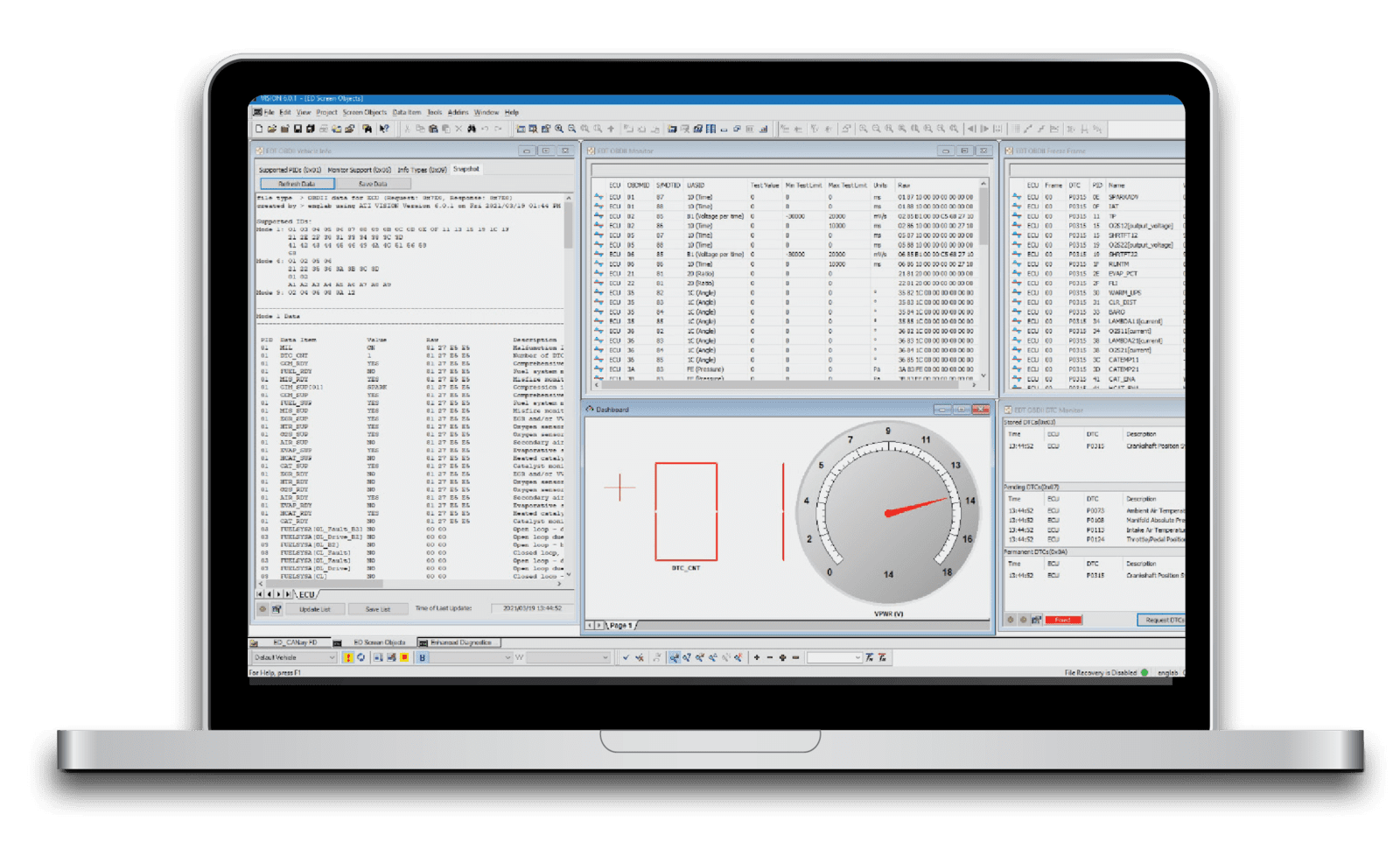

Basic and Enhanced Diagnostic Capabilities

In One Easy to Use Ecosystem

ATI offers diagnostics options within it's VISION Calibration and Data Acquisition Software eco-system, removing the need to juggle 3rd party software. VISION’s CAN OBDII Toolkit provides users with integrated support for legislated OBD functionality. Access the status of the various vehicle sub-systems to provide real-time data in addition to a standardized series of diagnostic trouble codes which allows you to rapidly identity malfunctions within the vehicle.

Diagnostics Features

Key Features:

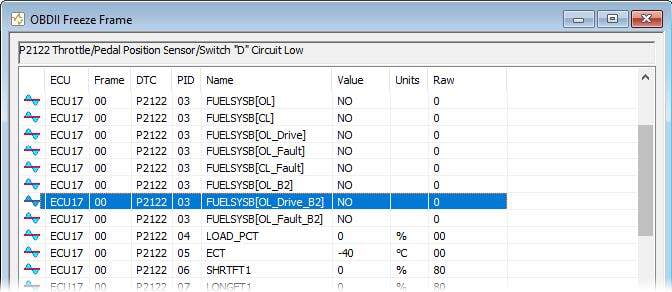

- Read live PIDs, INFOTYPEs, Monitors, and request freeze-frame data

- Request and clear DTCs (Diagnostic Trouble Codes) manually or automatically using trigger event expressions

- Generate an OBDII snapshot report manually or automatically using trigger event expressions.

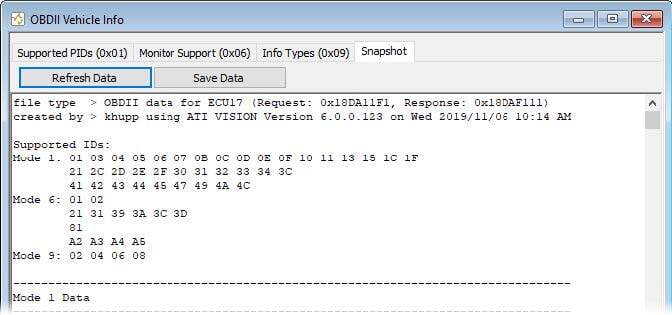

Snapshots

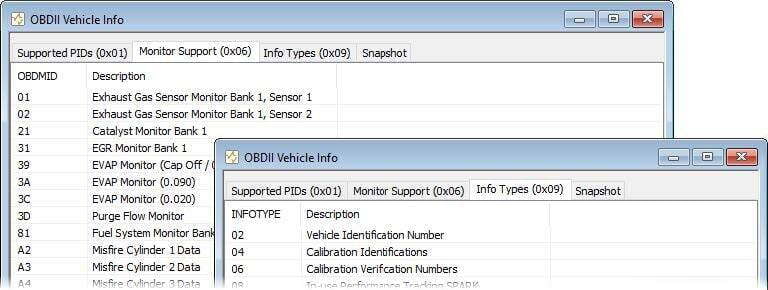

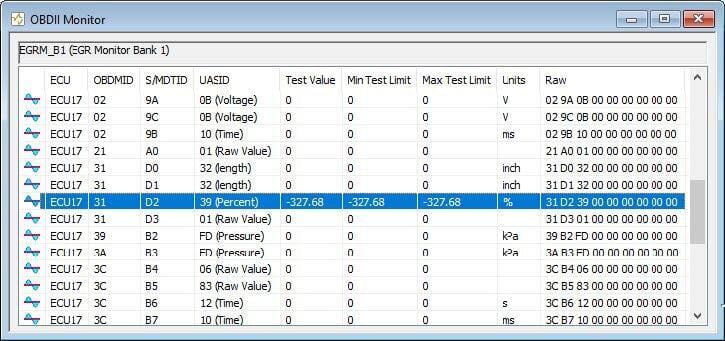

Monitor Support 0x06 (PID 00)

A detailed list of the OBDII monitor number and names from each of the connected ECUs.

Info Types 0x09

A detailed list of static vehicle information.

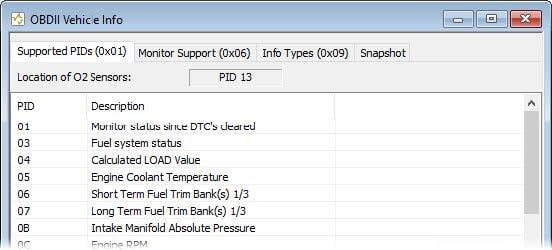

Supported PIDs

Freeze Frame Monitor

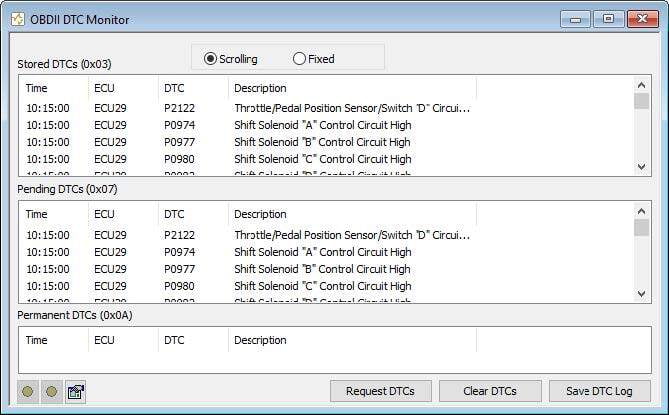

OBD II DTC Monitor

- Time - PC time when code was pulled

- ECU - The ECU containing the fault code

- DTC - Fault Code number

- Description - Description of the generated fault code

OBD II Monitor/Test

Key Features:

- Full integration with VISION’s Data Item Manager, screen controls, and recorders to optimize workflow.

- Simplify data collection and analysis by combining Measurement, Calibration and Diagnostics data onto a single recording.

- Auto-detect connected ECUs for quick discovery and connectivity. Manual overrides for custom applications.

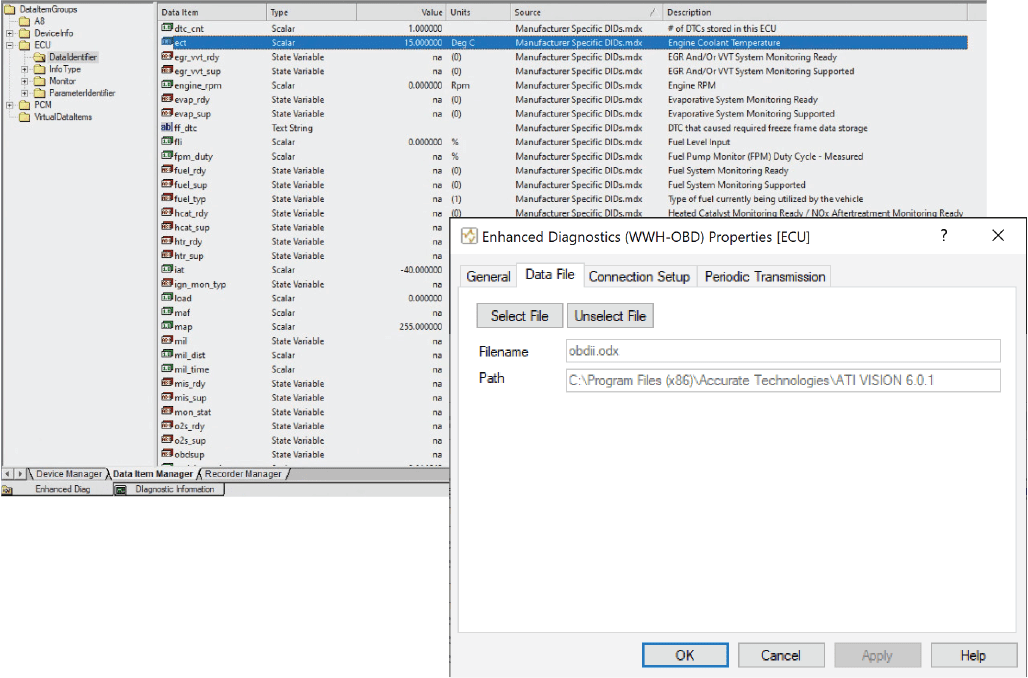

- Expand the number of available diagnostic data items by using a compatible ODX.

- Acquire data using UDS Periodic Transmission (service 0x2A) to increase DAQ throughput dramatically.

- Customer specific diagnostic features can be easily implemented using the extensive service and sub-functions available through XML-based Diagnostics via VISION’s COM API

- Comprehensive API documentation, quick-start guide, and SDK with example source code

Import OEM or User Defined DIDs

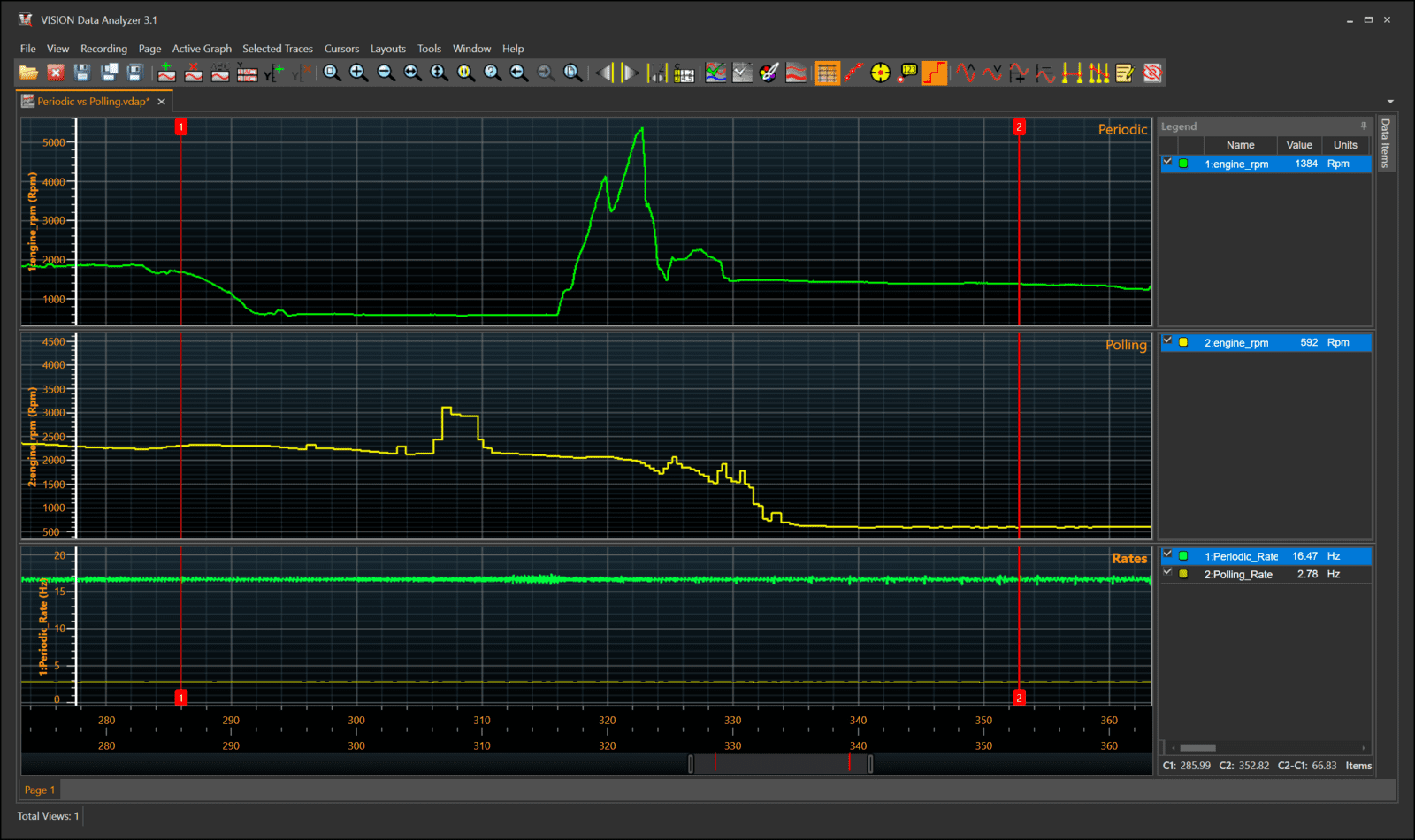

Periodic Transmission

Periodic Transmission, also known as Read Data By Periodic Identifier (Service 0x2A) can be configured for ECU’s that support it to benefit from faster retrieval of multiple DIDs in recorders. The interval between samples increases with each additional requested item when polling. UDS Periodic Transmission is similar to CCP/XCP DAQ lists and can acquire multiple items much more efficiently than polling dramatically increasing data acquisition throughput.

XML-Based Diagnostics via VISION API

Further OBDII and UDS services and sub-functions can be utilized via VISION’s API (Application Programming Interface) with custom tools or scripts for greater flexibility and automation of user specific diagnostic activities. API calls and responses are XML based and can be returned with optional augmented XML data replies to provide “human-readable” information such as DTC codes and descriptive text. The EDT Toolkit includes an installable Software Development Kit (SDK) to help programmers get up and running with the API and develop custom applications. Extensive documentation included.

| UDS Diagnostic Services | CAN OBDII | VISION Screen Objects | Supported by API |

| 0x01 | Powertrain Diagnostic Data | ✓ | ✓ | ✓ |

0x02 | Powertrain Freeze Frame Data | ✓ | ✓ | ✓ |

0x03 | Emission Related DTCs | ✓ | ✓ | ✓ |

| 0x04 | Clear Emission Related DTCs | ✓ | ✓ | ✓ |

| 0x06 | On-Board Monitoring Test Results | ✓ | ✓ | ✓ |

| 0x07 | Recent Emission-Related DTCs | ✓ | ✓ | ✓ |

| 0x08 | Control of On-Board System | ✓ | ||

| 0x09 | Vehicle Information | ✓ | ✓ | ✓ |

| 0x0A | Permanent Emission-Related DTCs | ✓ | ✓ | ✓ |

| 0x10 | Diagnostic Session Control | ✓ | ||

| 0x11 | ECU Reset | ✓ | ||

| 0x14 | Clear Diagnostic Information | ✓ | ||

| 0x19 | Read DTC Information | ✓ | ||

| 0x22 | Read Data by Identifier | ✓ | ||

| 0x23 | Read Memory by Address | ✓ | ||

| 0x24 | Read Scaling Data by Identifier | ✓ | ||

| 0x27 | Security Access | ✓ | ||

| 0x2C | Dynamically Define Data Identifier | ✓ | ||

| 0x2E | Write Data by Identifier | ✓ | ||

| 0x2F | Input/Output Control by Identifier | ✓ | ||

| 0x2A | Read Data by Periodic Identifier | ✓ | ||

| 0x31 | Routine Control | ✓ | ||

| 0x3D | Write Memory by Address | ✓ | ||

| 0x3E | Tester Present | ✓ | ||

| 0x85 | Control DTC Setting | ✓ |

With ATI’s CAN OBD and Enhanced Diagnostics toolkits, VISION can be setup to acquire OBDII PID and UDS DID data by utilizing services 1 and 22 or 2A respectively.

ATI Software License Models:

- STD - Single node (PC) locked license (one serial number on one device), 1st 12 months Dynamic Maintenance, updates and 24/7 technical support included. (Subsequent Dynamic Maintenance every 12 months).

- MUL - Multiple node (PC) locked license (one serial number on a specified number of devices). Same billing model as

- STD license's - Floating license tied to a physical USB key enabling multiple user access (not simultaneously). Same billing model as STD license.

- SVR - Server based license for large teams of users. Allows for the running of multiple instances in remote console sessions on the single server. Same billing model as STD license.

SUB - Optional Monthly subscription license – pay as you go per month – inclusive of dynamic maintenance and 24/7 technical support. Available for all the above license types.