PICOTURN - The Successful Solution To Detect Turbo Speed

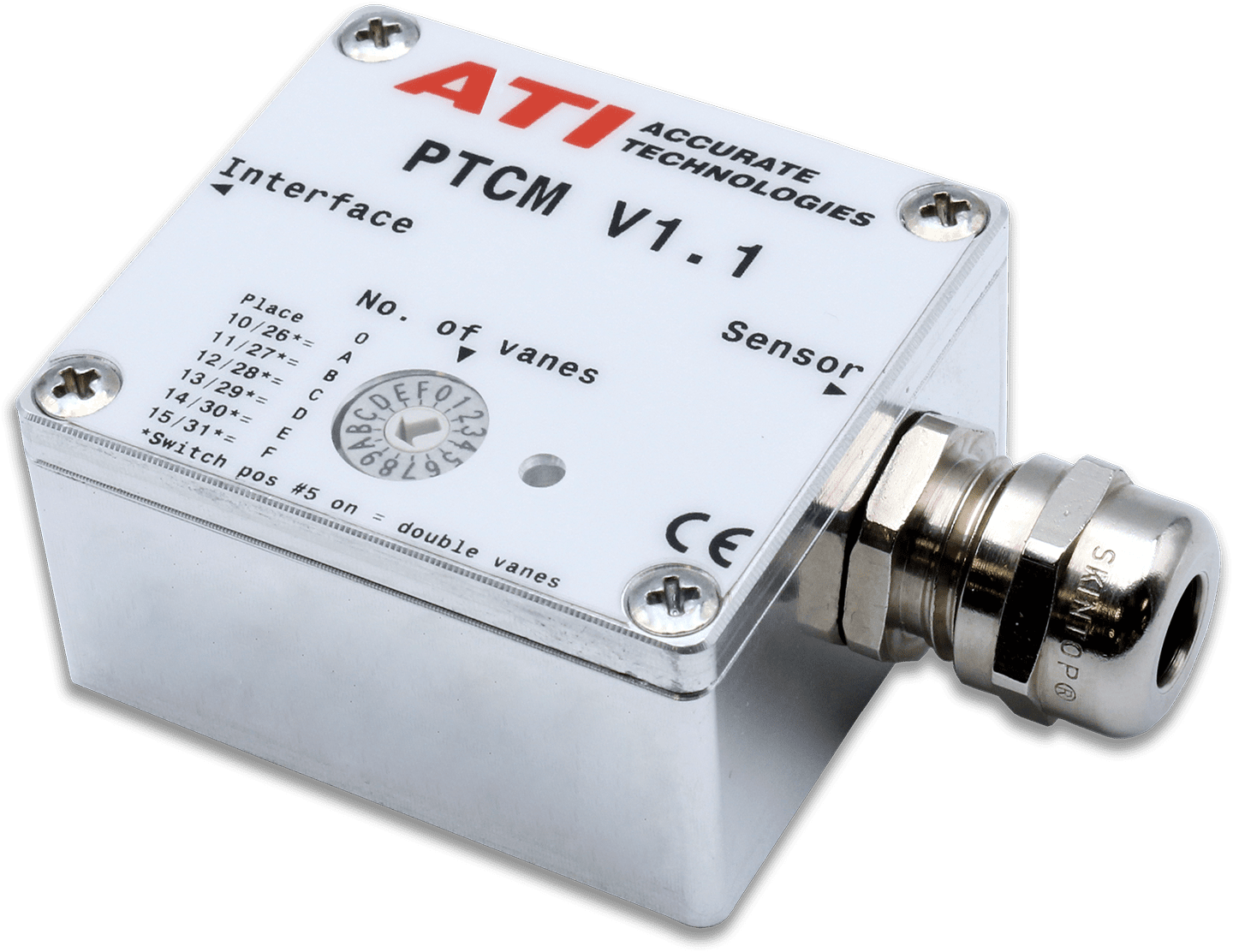

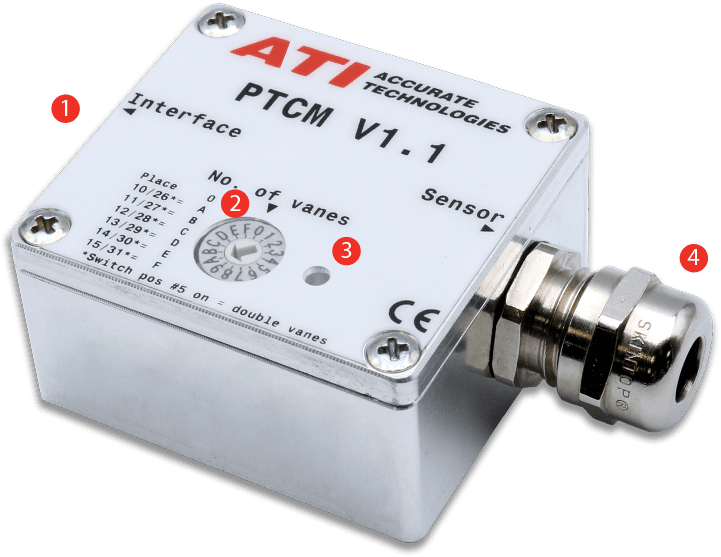

PICOTURN PTCM V1.1

Compact Controller

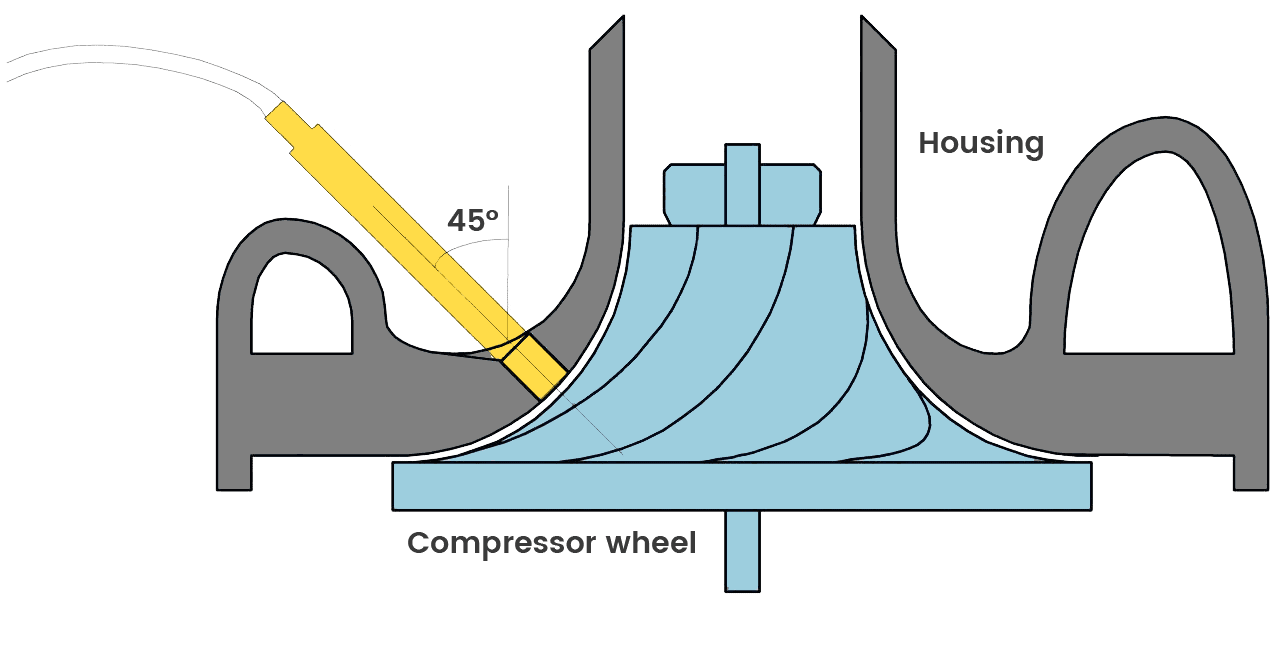

Accurate Technologies Inc. (ATI) offers the PICOTURN PTCM, a compact controller for turbocharger rotational speed sensors. Compared to optical or magnetic sensing systems, the PICOTURN system is proven as a rugged, reliable, simple, accurate and cost effective solution. The system’s functional principle is a 1MHz pulse induction with eddy current discrimination, using a compressor mounted solenoid sensor that detects and counts compressor vanes individually, generating a standard TTL/CMOS output signal.

FEATURES

- Compact size

- Supports all standard and H-type PICOTURN 1G sensors

- Adjustable number of vanes

- Designed for underbonnet use

System Overview

Specifications & Description

| Dimensions | 45mm x 50mm x 25mm (when sensor connected) |

| Protection Class | IP67 |

| Number of Vanes | 1 to 31 |

| Digital Output | TTL/CMOS (One impulse per N vanes, N = 1 to 31) |

| Analog Output | 0.5 to 4.5V |

| Temperature | -40°C to +85°C |

| Supply Voltage | 9 to 30 volts DC |

| * Excess temperature tolerated for short periods |

Sensor Specifications

| Sensor Tip Element Temperature |

| Sensor Body Dimensions |

| Protection Class |

| Standard sensor | –40°C to +250°C* (482°F) |

| H-type sensor | –40°C to +270°C* (518°F) |

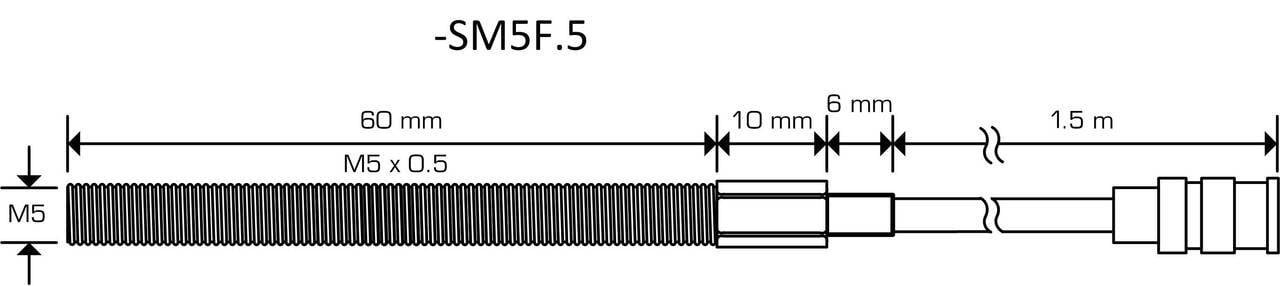

| Fine thread M5x0.5, with various lengths 25 to 60mm |

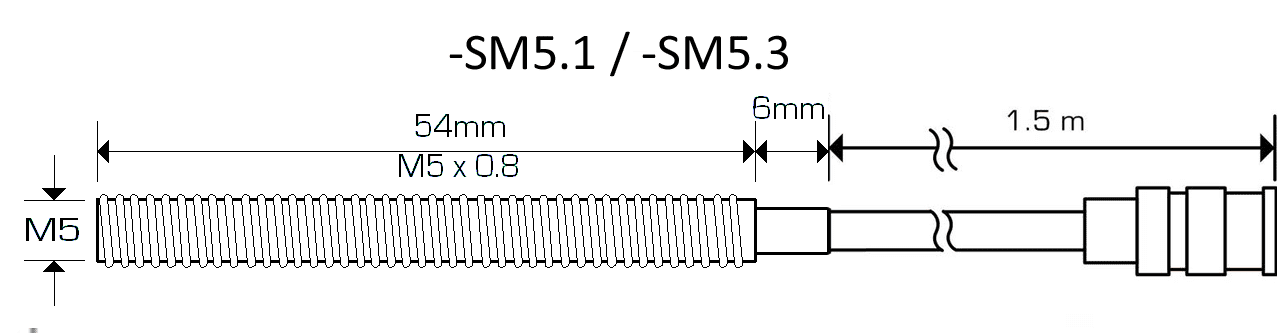

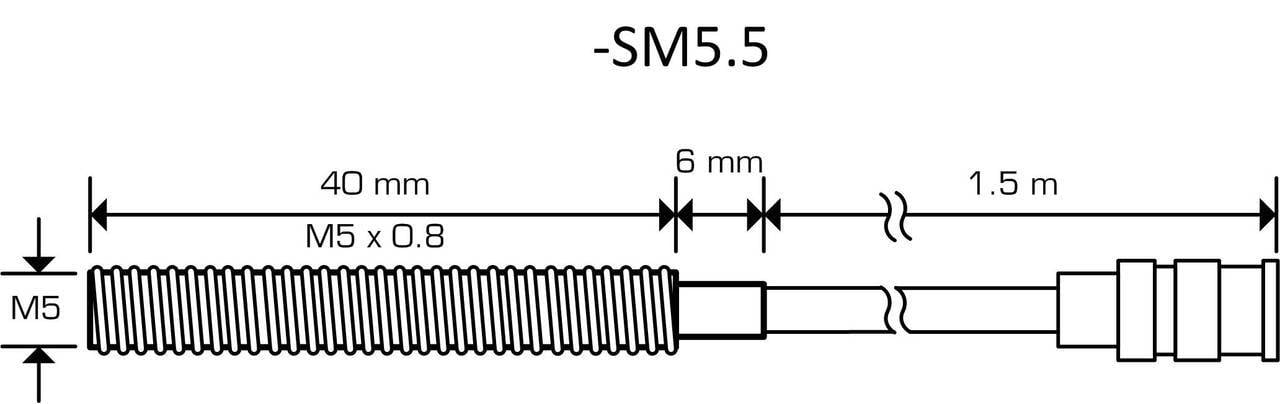

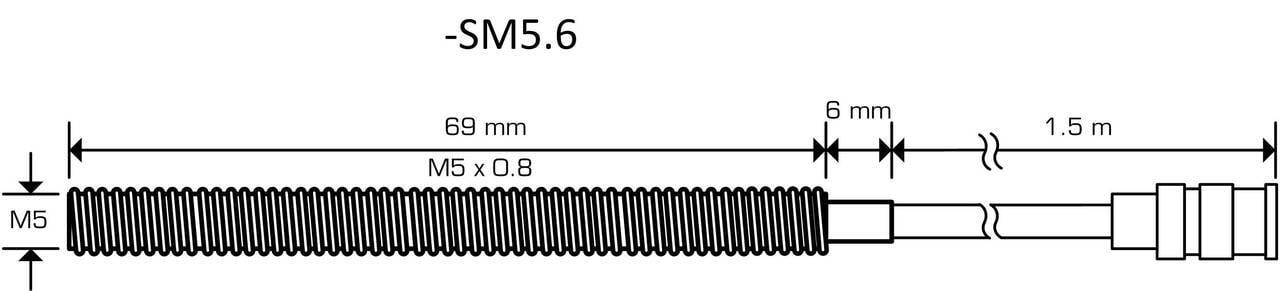

Standard thread M5x0.8, with various lengths 40 to 70mm |

| IP67 |

| Standard Sensor | H-type Sensor |

| Sensor Tip Element Temperature | r –40°C to +250°C* (482°F) | –40°C to +270°C* (518°F) |

Sensor Body Dimensions | Fine thread M5x0.5, with various lengths 25 to 60mm Standard thread M5x0.8, with various lengths 40 to 70mm |

| Protection Class | IP67 |

PTCM Order Information

| Part No. | Product | Description |

| 221030002 | PTCM ATI V1.1 | New reduced sized Controller/Signal Conditioning box with standard interface |

| 221040002 | PTCM-L ATI V1.1 | New reduced sized Controller/Signal Conditioning box with LEMO interface connector |

Sensor Options - 1G Sensors

H-types for higher temperature and higher sensitivity: -40°C to +270°C

| Part No. | Product | Sensor length /Thread length | Diameter | Cable length |

| 220180003 | PTSM-H 5.3 | 60 mm / 54 mm | M5 x 0.8 | 1.5m |

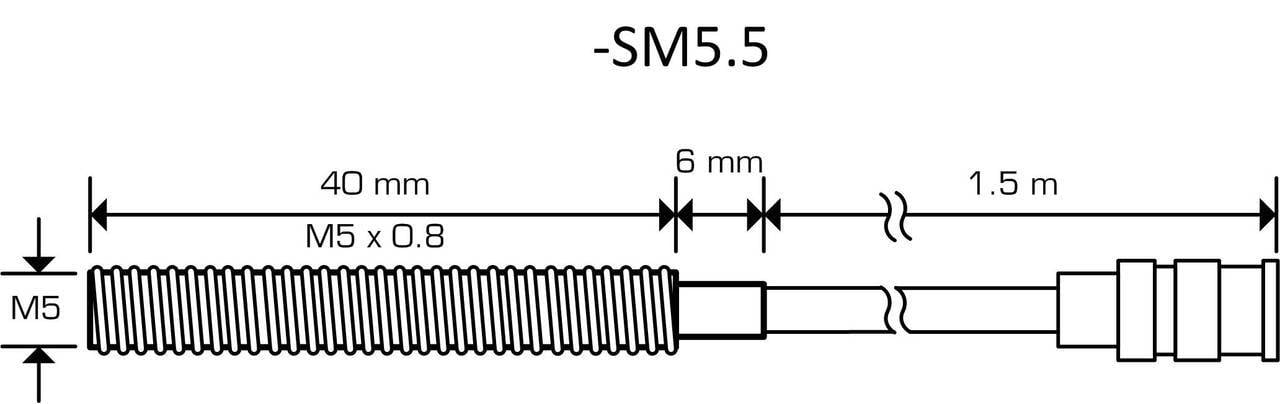

| 220180004 | PTSM-H 5.5 | 46 mm / 40 mm | M5 x 0.8 | 1.5m |

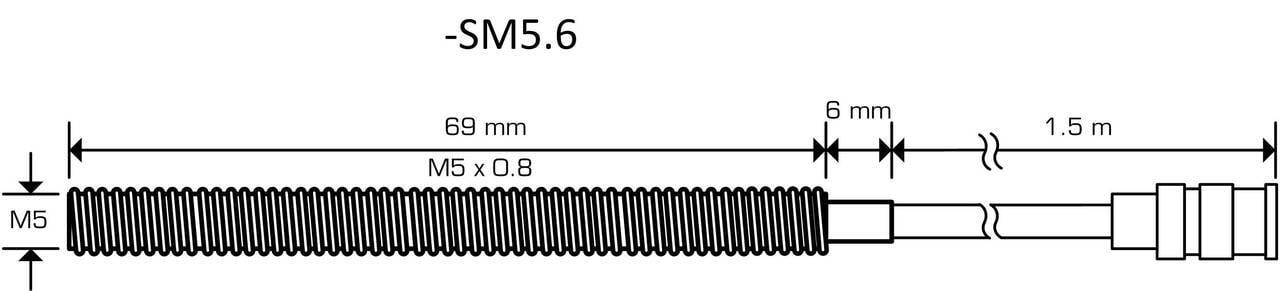

| 220180005 | PTSM-H 5.6 | 75 mm / 69 mm | M5 x 0.8 | 1.5m |

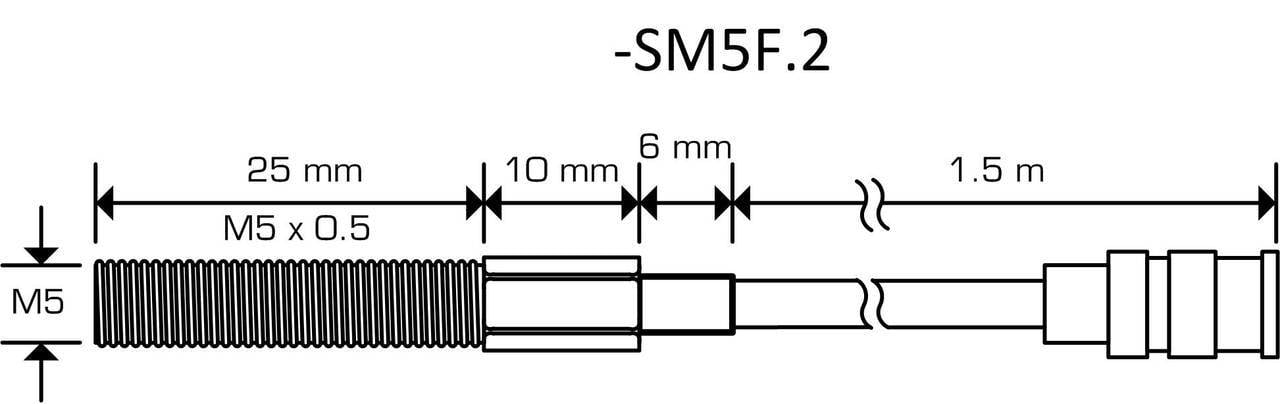

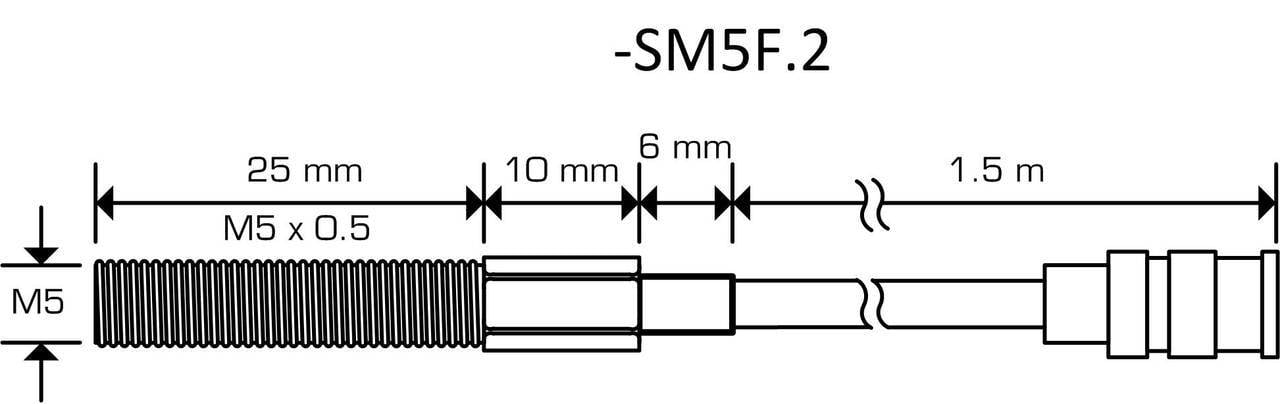

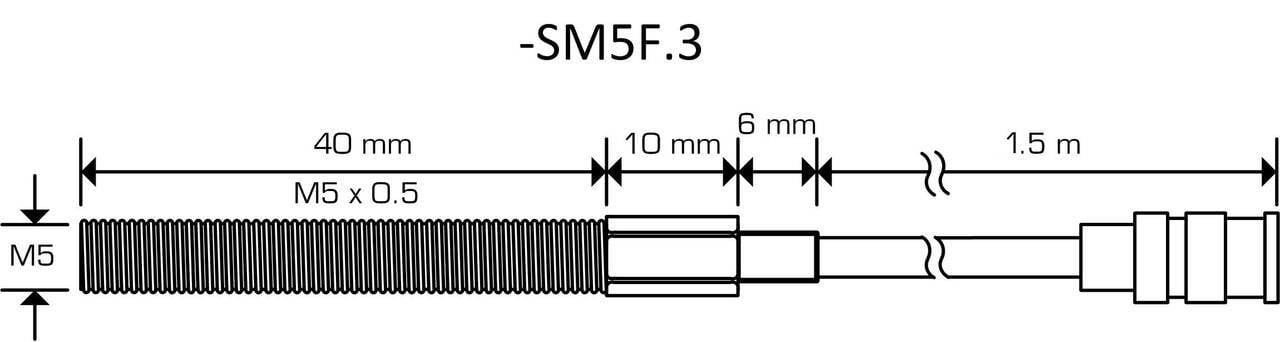

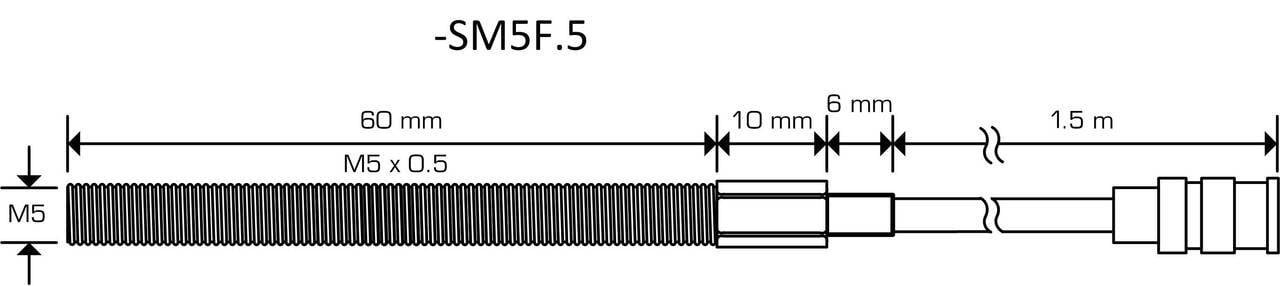

| 220180006 | PTSM-H 5F.2 | 41 mm / 25 mm | M5 x 0.5 | 1.5m |

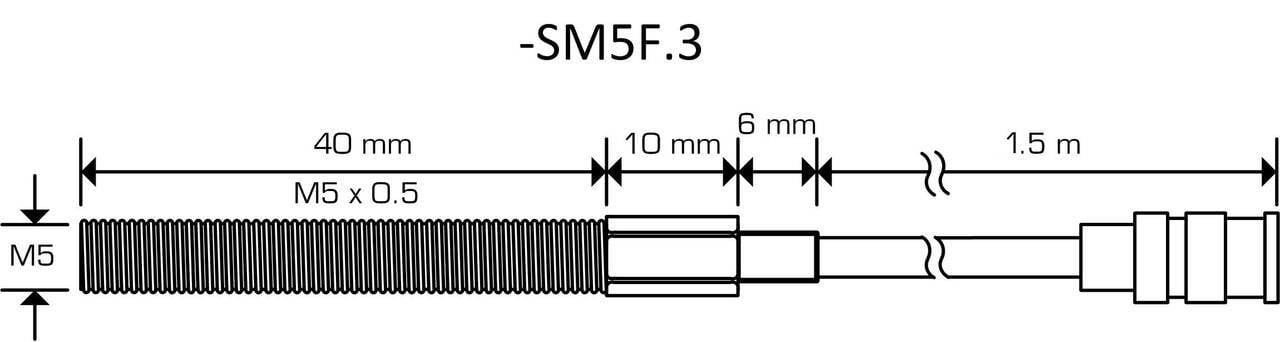

| 220180007 | PTSM-H 5F.3 | 56 mm / 40 mm | M5 x 0.5 | 1.5m |

| 220180008 | PTSM-H 5F.5 | 76 mm / 60 mm | M5 x 0.5 | 1.5m |

Standard Type: -40°C to +250°C

| Part No. | Product | Sensor length /Thread length | Diameter | Cable length |

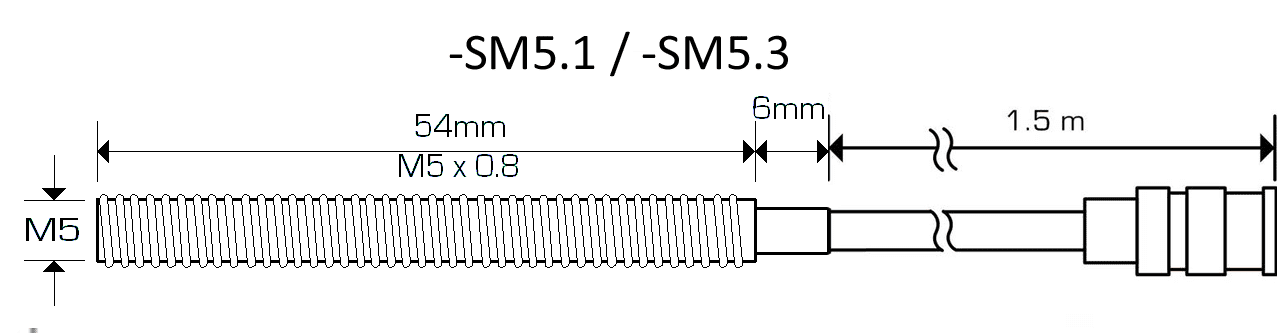

| 220150008 | PTSM 5.3 | 60 mm / 54 mm | M5 x 0.8 | 1.5m |

| 220150006 | PTSM 5.5 | 46 mm / 40 mm | M5 x 0.8 | 1.5m |

| 220150012 | PTSM 5.6 | 75 mm / 69 mm | M5 x 0.8 | 1.5m |

| 220150004 | PTSM 5F.2 | 41 mm / 25 mm | M5 x 0.5 | 1.5m |

| 220150014 | PTSM 5F.3 | 56 mm / 40 mm | M5 x 0.5 | 1.5m |

| 220150016 | PTSM 5F.5 | 76 mm / 60 mm | M5 x 0.5 | 1.5m |

Accessories

| Part No. | Product | Description |

| 220320001 220320002 220320003 | PTCM-1.5-nc PTCM-3.0-nc PTCM-1.5-BNC | System interface power cable, open ends System interface power cable, open ends System interface power cable, BNC connectors for signals, banana jack connectors for power | 1.5m length 3.0m length 1.5m length |

| 220320004 | PTCM-L | System Cable LEMO open ended | 2m length |

| 220330001 | PTCM Mounting Plate | Mounting plate including screws |

| 220030002 | PTSM 5F.x Clamping nut | For fine thread sensors -SM5F.x |

| 220360004 | ATI PTCM coverfoil | Faceplate |

| 220370001 | PTCM coverseal | Seal for faceplate |

PICOTURN - 1G

The Original System for Turbocharger Speed Measurement

Sensor Specifications

| Sensor Tip Element Temperature | Standard sensor: –40°C to +250°C* (482°F) H-type sensor: –40°C to +270°C* (518°F) |

| IP67 rating | Yes |

| Sensor Body Dimensions | Fine thread M5x0.5, with various lengths 25mm to 60mm Standard thread M5x0.8, with various lengths 40mm to 70mm |

| Extension cable | Max length 1.5 meters / 2.5 meters |

| * Excess temperature tolerated for short periods |

H-types for higher temperature and higher sensitivity: -40°C to +270°C Sensor Head Temperature Range; 1.5m Cable Length

| Sensor | Part Number | Sensor Length | Thread Length | Diameter | Drawing |

| PT-H-SM5.3 | 220180003 | 60 mm | 54 mm | M5 x 0.8 |  |

| PT-H-SM5.5 | 220180004 | 46 mm | 40 mm | M5 x 0.8 |  |

| PT-H-SM5.6 | 220180005 | 75 mm | 69 mm | M5 x 0.8 |  |

| PT-H-SM5F.2 | 220180006 | 41 mm | 25 mm | M5 x 0.5 |  |

| PT-H-SM5F.3 | 220180007 | 56 mm | 40 mm | M5 x 0.5 |  |

| PT-H-SM5F.5 | 220180008 | 76 mm | 60 mm | M5 x 0.5 |  |

Standard Type: -40°C to +250°C Sensor Head Temperature Range; 1.5m Cable Length

| Sensor | Part Number | Sensor Length | Thread Length | Diameter | Drawing |

| PT-SM5.3 | 220150008 | 60 mm | 54 mm | M5 x 0.8 |  |

| PT-SM5.5 | 220150006 | 46 mm | 40 mm | M5 x 0.8 |  |

| PT-SM5.6 | 220150012 | 75 mm | 69 mm | M5 x 0.8 |  |

| PT-SM5F.2 | 220150004 | 41 mm | 25 mm | M5 x 0.5 |  |

| PT-H-SM5F.3 | 220150014 | 56 mm | 40 mm | M5 x 0.5 |  |

| PT-SM5F.5 | 220150016 | 76 mm | 60 mm | M5 x 0.5 |  |

Accessories

| Part No. | Product | Description |

| 220120001 | Extension Cable | SMB-SMB, for sensors | 1.5m length |

| 220030002 | PTSM 5F.x Clamping nut | For fine thread sensors-SM5F.x |

The Measuring Method for Rotational Speed Sensors for Turbochargers

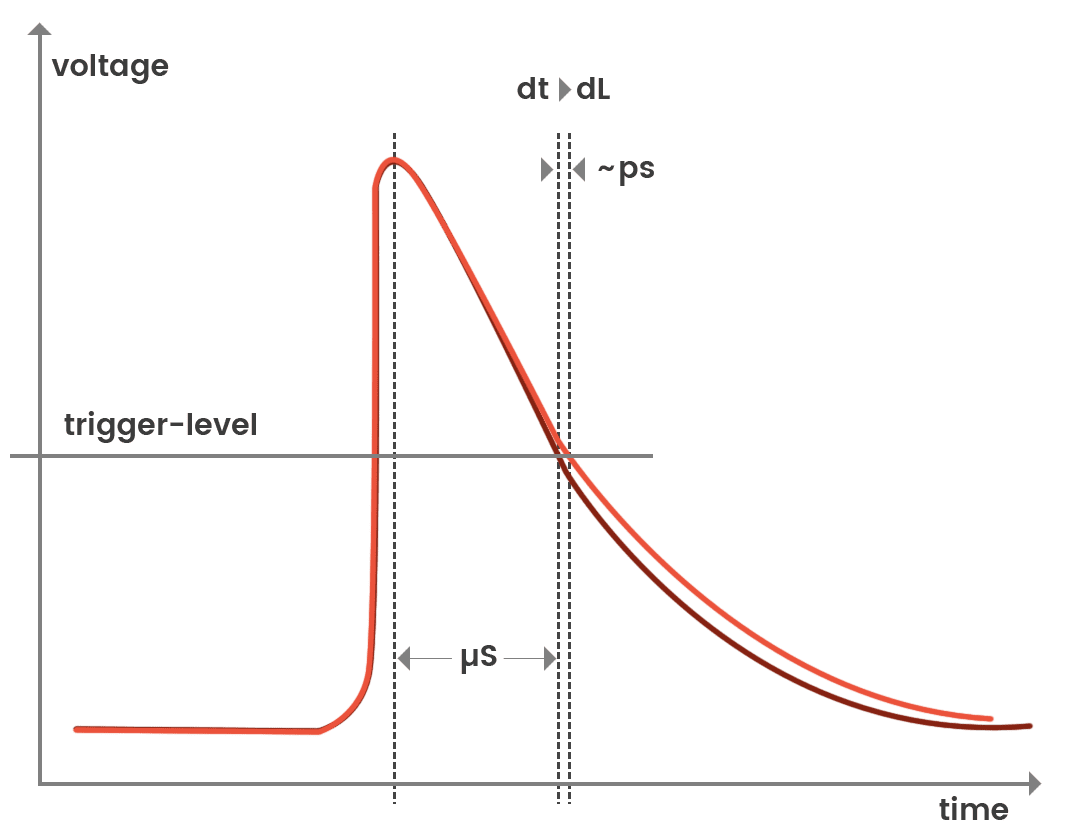

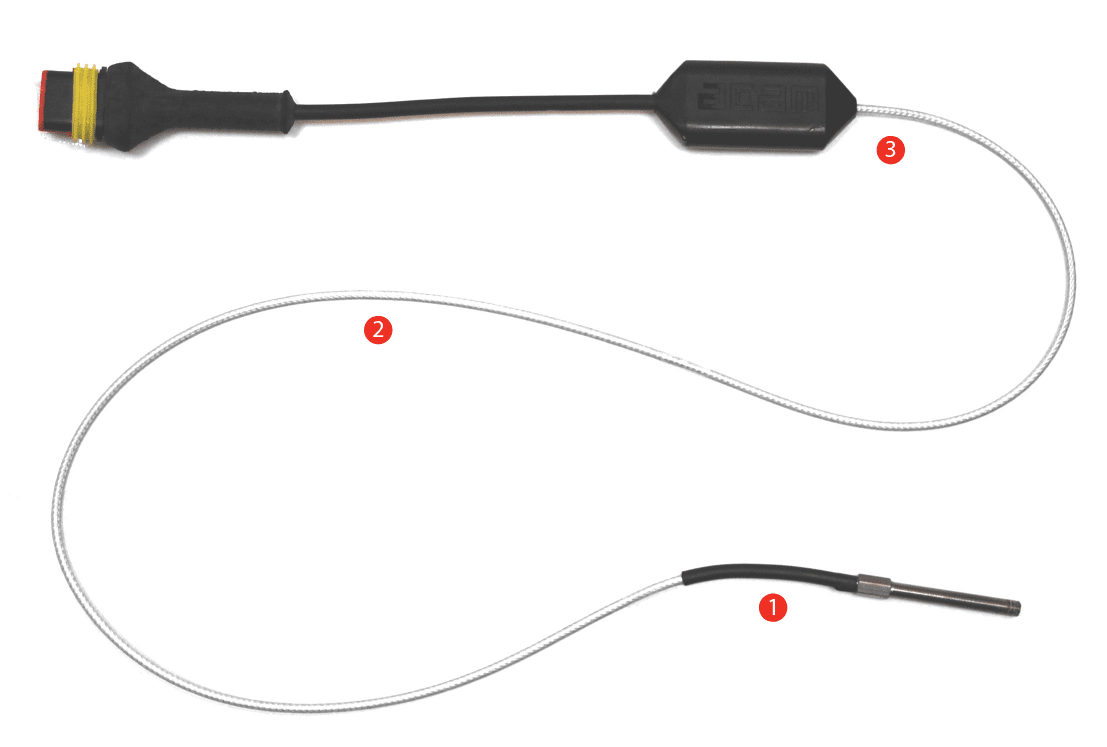

The sensor is made of a simple coil with a ferrite core. Together with a resistor this forms an R-L network, the time constant of which is measured by a TDC. Placing a vane of the compressor wheel in front of the coil will change the time constant of the R-L network. This is caused by the influence of the vane metal on the parameters of the coil inductance L. A DSP-unit following the TDC measurement unit processes the time data, identifies the passing of each single vane and calculates the rotational speed.

The time measurement is done with very high precision. The resolution is about 125 ps. The time constant of the R-L network can be very small, allowing high sampling rates in the range of 1 to 3 million samples per second.

The physical effect of the vane metal on L varies, depending on the metal. The PICOTURN system is currently optimized for aluminum wheels. The system is basically suitable for other metals, too. However, the measurement sensitivity, and correspondingly the required distance between sensor and wheel, will vary depending on material and vane thickness. When using titanium wheels the system requires the use of High Temp Probes.

PICOTURN - 2G

Rotational Speed Sensors

The PICOTURN system benefits from high sensitivity, allowing a large distance between sensor and the rotating vanes in the range of 1mm at 0.6mm vane thickness. Various sensors are available to accommodate numerous user cases differentiated by the length and thread of the sensor head.

The PTSM-H series benefits from enhanced sensitivity, enabling use with titanium wheel and other critical applications where higher temperatures are a priority. The second generation PICOTURN sensing system - the PT2G - is summarized in the datasheet.

Sensor Specifications

| Temperature | Cable and electronics Sensor tip: Standard Sensor tip: H-type | –40°C to +180°C* (356°F) –40°C to +250°C* (482°F) –40°C to +270°C* (518°F) |

| Dimensions | Fine thread M5x0.5 with various lengths 25mm to 60mm Standard thread M5x0.8 with various lengths 40mm to 70mm |

| Length of sensor element and its cable | From body to ASIC From ASIC to connector Total length sensor element | approx. 0.75 meter approx. 0.12 meter approx. 1.00 meter |

| Extension cable | Max length | 10 meters |

| * Excess temperature tolerated for short periods |

H-types for higher temperature and higher sensitivity: -40°C to +270°C Sensor Head Temperature Range; 0.95m Cable Length

| Sensor | Part Number | Sensor Length | Thread Length | Diameter | Drawing |

| PT2G-H-SM5.3 | 220160015 | 60 mm | 54 mm | M5 x 0.8 |  |

| PT2G-H-SM5.5 | 220160017 | 46 mm | 40 mm | M5 x 0.8 |  |

| PT2G-H-SM5.6 | 220160018 | 75 mm | 69 mm | M5 x 0.8 |  |

| PT2G-H-SM5F.2 | 220160016 | 41 mm | 25 mm | M5 x 0.5 |  |

| PT2G-H-SM5F.3 | 220160013 | 56 mm | 40 mm | M5 x 0.5 |  |

| PT2G-H-SM5F.5 | 220160014 | 76 mm | 60 mm | M5 x 0.5 |  |

Standard Type: -40°C to +250°C Sensor Head Temperature Range; .95m Cable Length

| Sensor | Part Number | Sensor Length | Thread Length | Diameter | Drawing |

| PT2G-SM5.3 | 220160010 | 60 mm | 54 mm | M5 x 0.8 |  |

| PT2G-SM5.5 | 220160019 | 46 mm | 40 mm | M5 x 0.8 |  |

| PT2G-SM5.6 | 220160006 | 75 mm | 69 mm | M5 x 0.8 |  |

| PT2G-SM5F.2 | 220160004 | 41 mm | 25 mm | M5 x 0.5 |  |

| PT2G-SM5F.3 | 220160012 | 56 mm | 40 mm | M5 x 0.5 |  |

| PT2G-SM5F.5 | 220160008 | 76 mm | 60 mm | M5 x 0.5 |  |

All specifications are subject to change without notice.

*This product is not available in all regions.