Key Differences and Why It Matters for Modern Vehicles

Ethernet is a family of networking technologies used for local area networks (LANs). Traditional or regular Ethernet is widely used in business, home, and data center environments due to its high-speed data transfer, reliability, and standardization. It is based on the IEEE 802.3 standard, providing speeds ranging from 10 Mbps to 100 Gbps and beyond.

What is Automotive Ethernet?

Automotive Ethernet is a variation of Ethernet specifically adapted to meet the stringent requirements of automotive environments. It is defined by the IEEE 802.3 and OPEN (One-Pair EtherNet) Alliance standards, which include adaptations to manage the harsh operating conditions, safety-critical requirements, and real-time data needs found in vehicles.

Key Differences Between Automotive Ethernet and Regular Ethernet

- Topology and Cable Types

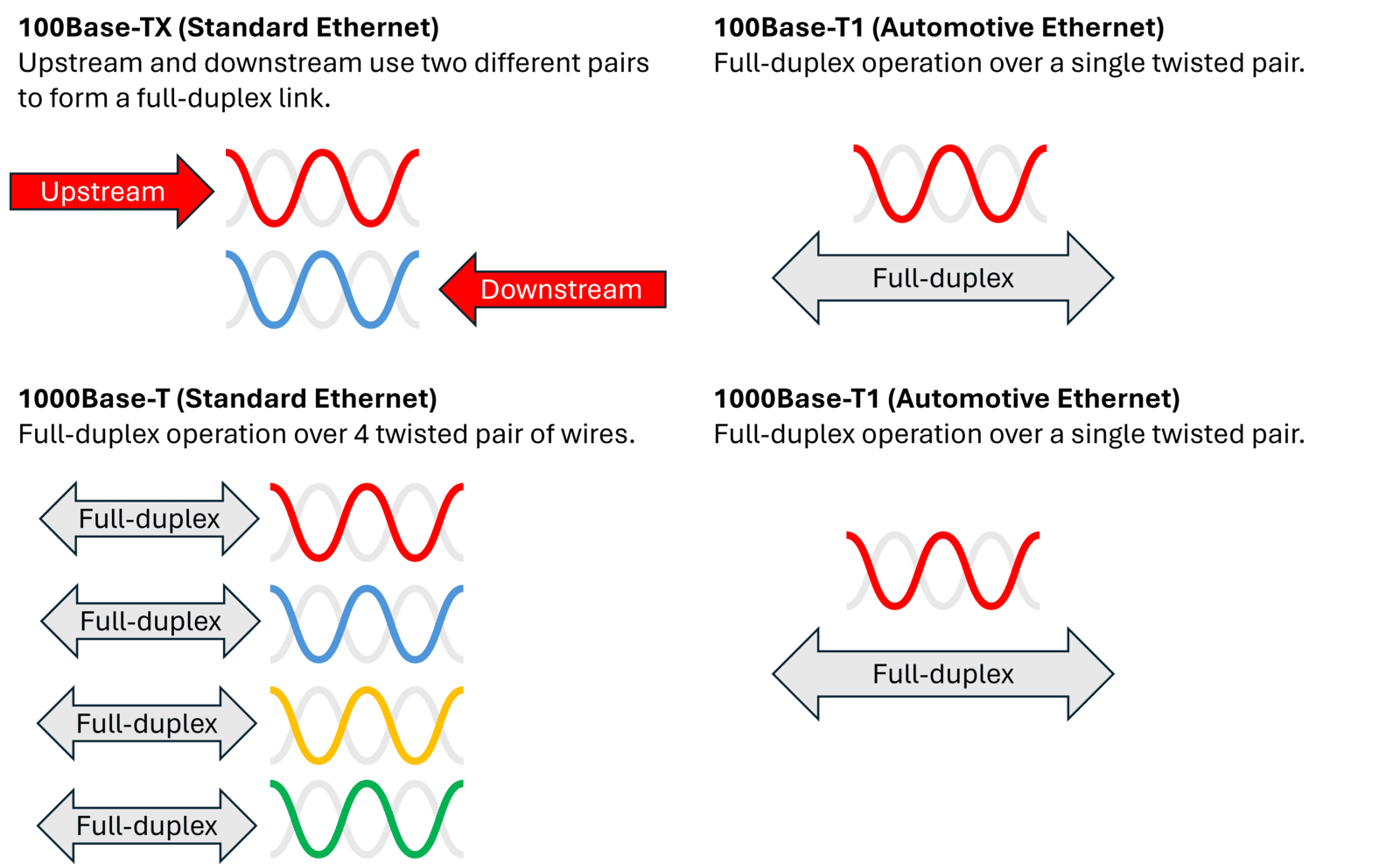

- Regular Ethernet: Uses a variety of physical media, including copper cables (Cat5e, Cat6), fiber optics, and twisted pairs. Most commonly used topologies are star or tree architectures in offices and homes, requiring multiple wires for full-duplex communication.

- Automotive Ethernet: Optimized for one-pair twisted cables (often unshielded) due to cost, space, and weight constraints. It typically supports single-pair Ethernet (SPE) configurations that transmit data and power over a single twisted pair, reducing weight and complexity in cars. The dominant topology in vehicles is a point-to-point or daisy-chain connection, tailored to minimize cabling complexity.

- Speed and Bandwidth

- Regular Ethernet: Ranges from 10 Mbps to multi-gigabit speeds (100 Gbps+). Ethernet can easily be scaled for high-bandwidth tasks in enterprise and data-center applications.

- Automotive Ethernet: Designed to meet automotive bandwidth requirements, with current speeds typically ranging from 10 Mbps (100BASE-T1) to 1 Gbps (1000BASE-T1). Higher bandwidth options are emerging, but the focus is on efficiently handling in-car communication needs like camera feeds, radar, LiDAR, and sensor data rather than internet traffic.

- Latency and Determinism

- Regular Ethernet: While it offers high throughput, regular Ethernet lacks real-time guarantees. Latency can vary depending on traffic and network configuration. For general computing, this variability is acceptable.

- Automotive Ethernet: Requires low-latency and deterministic communication to meet the real-time demands of automotive applications, such as ADAS and vehicle control systems. Technologies like Time-Sensitive Networking (TSN) are employed in Automotive Ethernet to ensure timely delivery of critical data.

- Environmental Resilience

- Regular Ethernet: Primarily operates in controlled environments like homes, offices, and data centers, where temperature, vibration, and electromagnetic interference (EMI) are minimal.

- Automotive Ethernet: Built for extreme automotive environments, Automotive Ethernet systems must withstand temperature fluctuations, moisture, high EMI, and physical vibrations. Automotive Ethernet cables and connectors are ruggedized and tested for reliability in these harsh conditions.

- Power Consumption

- Regular Ethernet: Power over Ethernet (PoE) is commonly used in regular Ethernet to deliver power to devices like IP cameras and wireless access points. However, the power requirements in regular Ethernet can be relatively high for certain automotive applications.

- Automotive Ethernet: Designed with energy efficiency in mind, especially for electric and hybrid vehicles. Automotive Ethernet provides low-power communication, which is essential for minimizing battery drain in energy-conscious automotive systems. Additionally, technologies like Power over Data Line (PoDL) allow power and data transmission over a single pair of wires, reducing the complexity and power consumption further.

- Cost Considerations

- Regular Ethernet: Focused on high-speed, high-performance networking, cost is often secondary to performance and scalability in regular Ethernet.

- Automotive Ethernet: Aims to minimize costs while meeting stringent safety and performance standards. The use of single-pair cabling, simpler connectors, and optimized hardware keeps Automotive Ethernet both cost-effective and lightweight, which is crucial for the automotive industry.

- Standards and Safety

- Regular Ethernet: Ethernet in traditional IT environments follows IEEE 802.3 standards, ensuring interoperability and performance.

- Automotive Ethernet: While also based on IEEE 802.3 standards, Automotive Ethernet integrates additional standards and protocols for safety and reliability, including the ISO 26262 functional safety standard. Critical vehicle systems like ADAS, braking, and engine management rely on the deterministic and fail-safe capabilities of Automotive Ethernet, making safety an integral part of its design.

Why Automotive Ethernet is Critical for Modern Vehicles

- Higher Bandwidth: Supports data-intensive applications like 360-degree cameras, radar, and LiDAR systems, essential for autonomous driving and ADAS.

- Scalability: As cars become more connected, with more devices requiring network access, Ethernet offers the scalability to accommodate future growth.

- Simplification: Reduces the number of cables and connectors needed, simplifying vehicle wiring and reducing both weight and cost.

- Interoperability: Automotive Ethernet is part of the broader Ethernet ecosystem, allowing easier integration of in-car systems with external networks and devices.