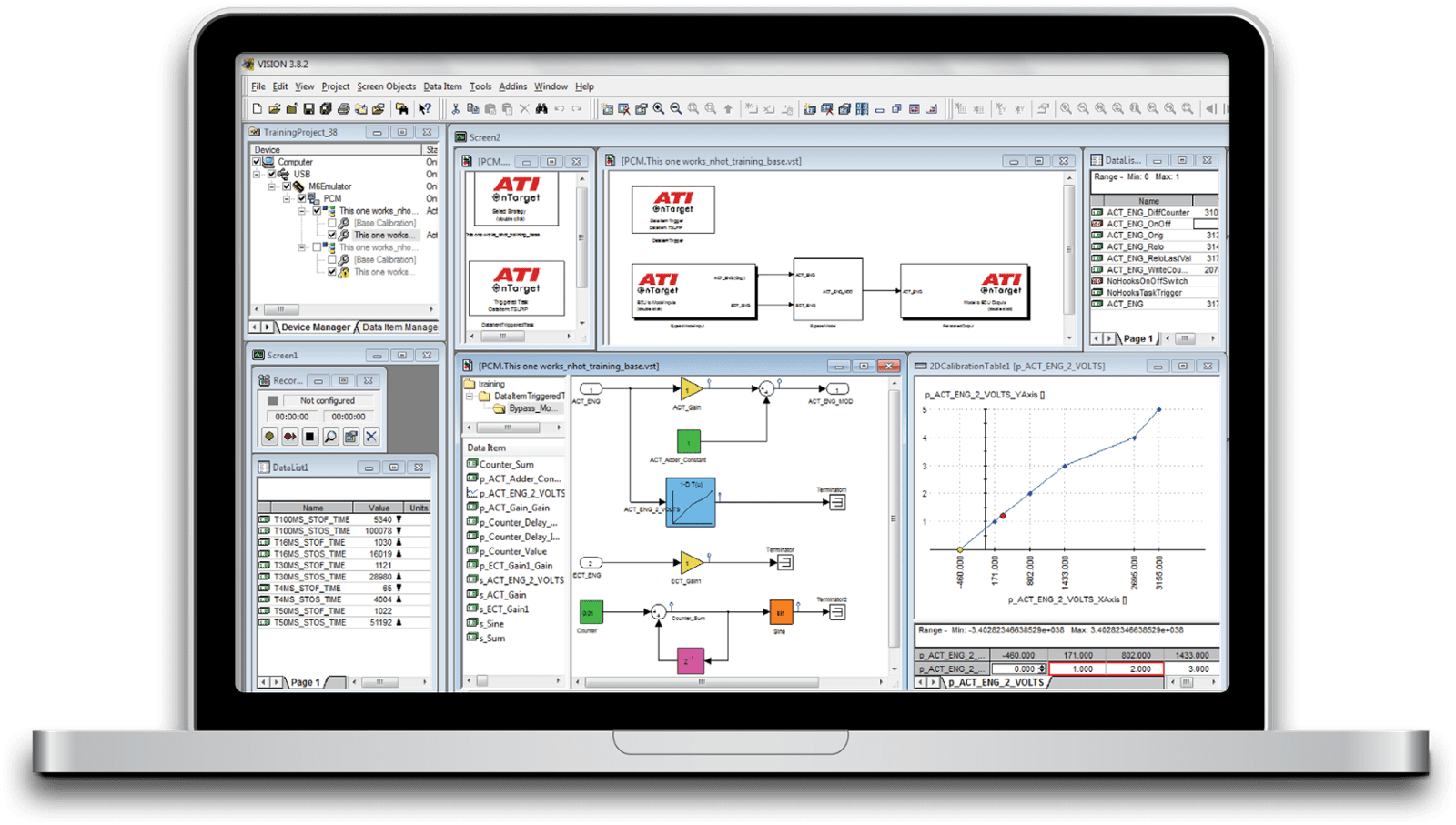

ECU Rapid Prototyping Software

- No-Hooks Toolkit - Allows users to bypass control variables in the ECU’s RAM that are normally only viewable or measurable

- Advanced No-Hooks Toolkit - extends it to allow ECU functionality to be modified by user defined functions, without access to the original ECU source code or the need for other applications such as MATLAB/Simulink.

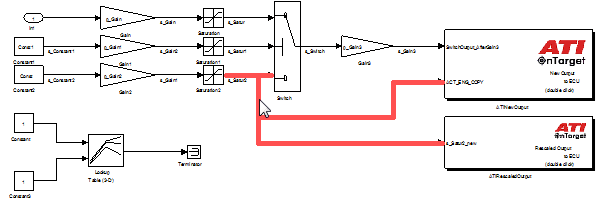

- OnTarget Toolkit - Allows bypassed variables to be integrated with model outputs into the production ECU executables without any modifications to the ECU source

- Model Browser - Provides a sophisticated user interface of Simulink models from within VISION software to enhance OnTarget or xPC Target calibration and data acquisition functionality.

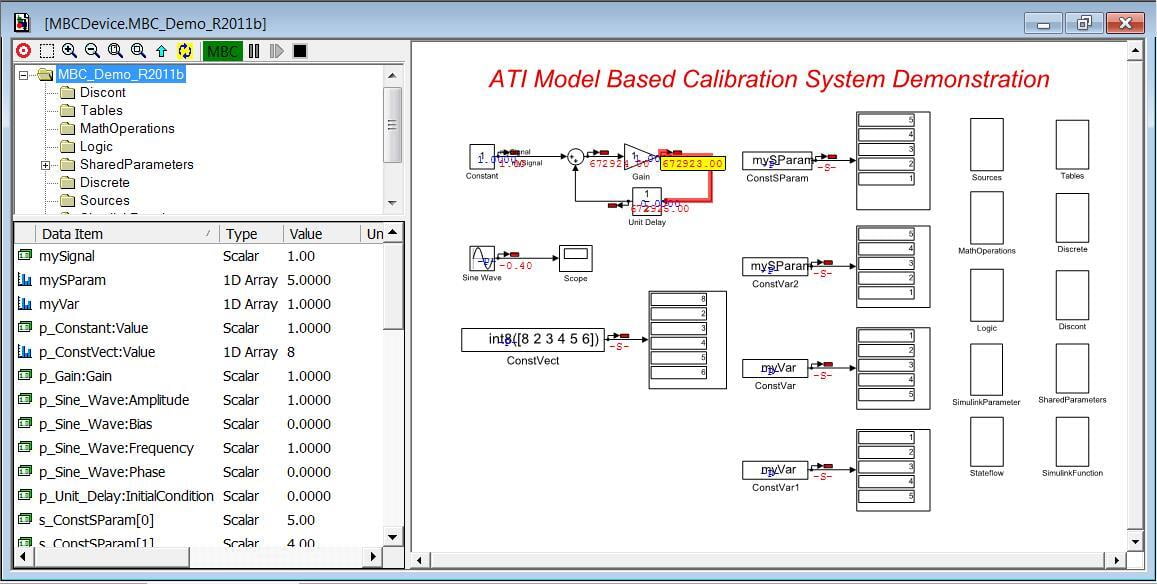

- Model Based Calibration (VISION MBC) Toolkit - MBC is the implementation of a Model-in-the-loop (MIL) system. The MathWorks’ tools, MATLAB® and Simulink®, provide the modeling environment and VISION MBC provides the ‘in-the-loop’ capability, integrating VISION with the model as it runs natively within the Simulink® environment.

No-Hooks

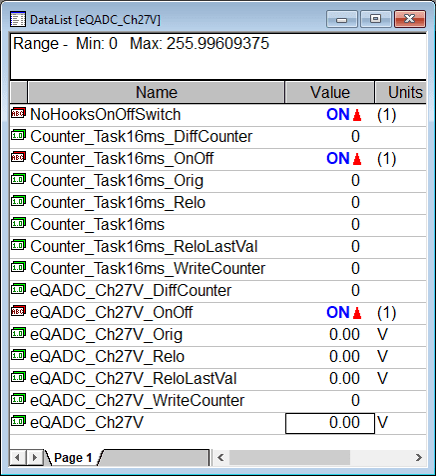

With only the information needed for traditional calibration and using an ECU interface, Base No-Hooks allows the user to control and adjust ECU controlled global RAM variables in the ECU. Use Base No-Hooks to select variables and convert them to calibratable variables and use ATI's VISION Software interface to easily make changes. Simplify and expedite tasks, enable creativity, and lower costs using ATI’s Base No-Hooks.

Features:

- Lower cost than hardware solutions

- Bypass variables with calibratable parameters

- Rapid prototyping functionality is independent of the ECU interface

- Conduct rapid prototyping on production intent hardware, providing functional confidence that will translate to saved development time and money

- No need for original ECU code, eliminating delays and cost for iterative changes between groups or companies

- Allows calibration, data acquisition, post analysis and software rapid prototyping in the same application

- Use the ECU hex image generated by No-Hooks to flash as many targets as needed

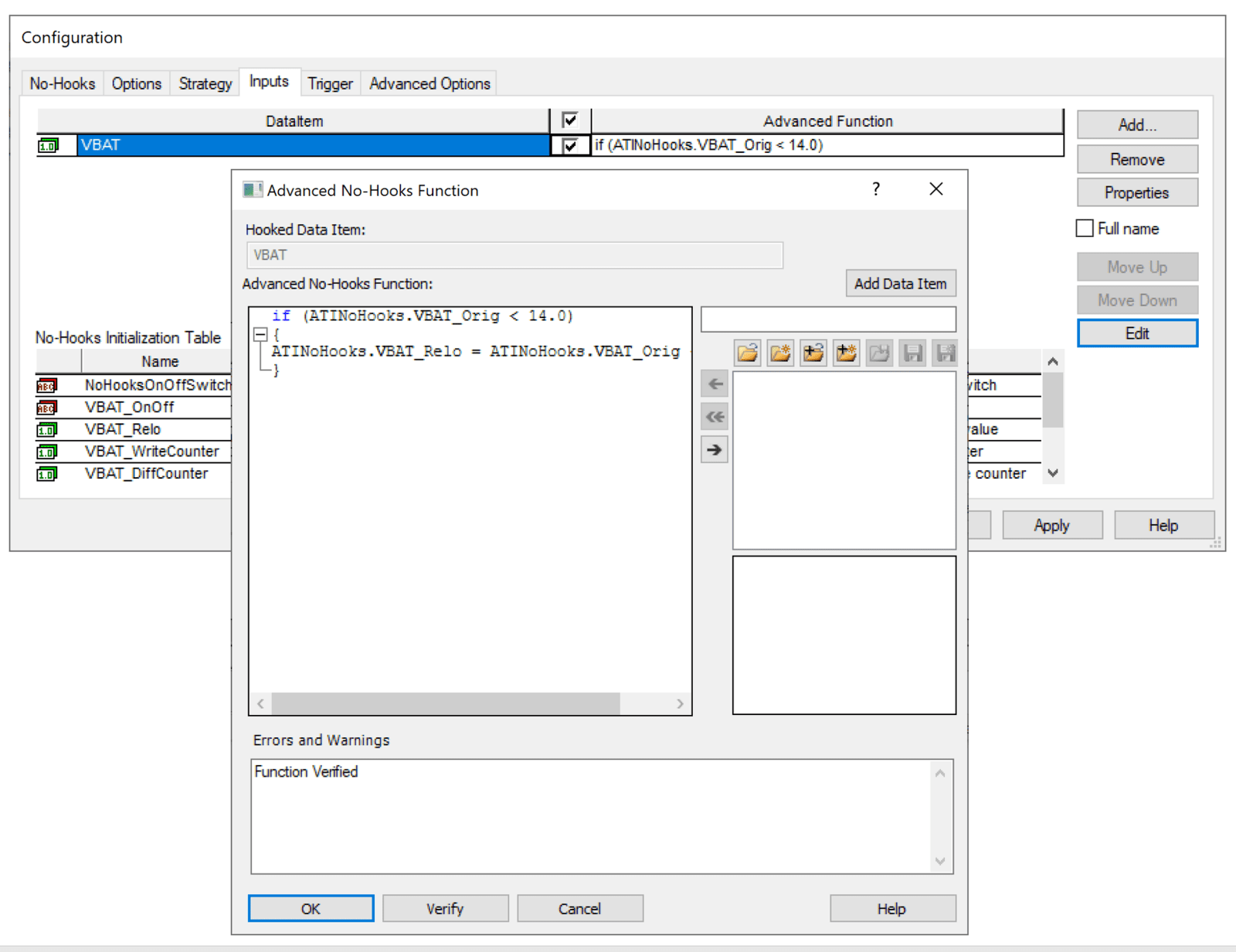

Advanced No-Hooks

Features:

- User defines a function in C like syntax for the dynamic hook value using VISION data items, constants, and Advanced No-Hooks variables

- No-Hooks DLL creates relocation and trigger code

- Function Library and function editing with syntax highlighting

- Requires only No-Hooks DLL for target CPU

- No need to implement “hooks” in advance of using Advanced No-Hooks

- Implementation of Advanced No-Hooks can be performed at any time in the development process

- No re-compiling of the original source code is needed

- Simultaneously view the original variable value along with the bypassed value and values declared in the Advanced No-Hooks functions

- No additional hardware or software tools other than ATI’s VISION with No-Hooks and Advanced No-Hooks

- All ATI’s Rapid Prototyping products work seamlessly with the calibration, signal monitoring, data acquisition, and post analysis capability of the VISION Calibration and Data Acquisition Software

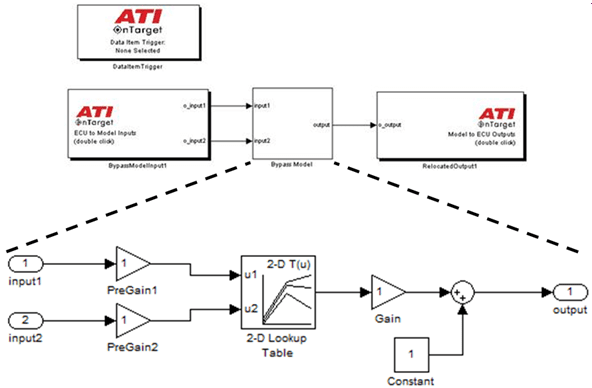

OnTarget

OnTarget enables the expanded capability to add custom model based control algorithm code to replace the existing ECU code for calculating selected RAM variables on the ECU under test, also called the Target. In the No-Hooks tradition, there is no need for access to or modification of the ECU source code; all that is needed is the ECU executable and description files.

OnTarget was designed to make use of Simulink® models to develop these alternative control algorithms. Simulink is a platform for simulation and Model-Based Design from MathWorks. OnTarget includes the appropriate Simulink libraries (block sets) and target build files for generating C-code using Simulink Coder™ (formerly Real-Time Workshop®) and compiling the code with various compilers (like the free ATI GNU compilers).

Features:

- All the features of No-Hooks Rapid Prototyping

- Bypass variables with outputs from a Simulink® model, allowing the addition of an entirely new control algorithm to the existing ECU code without modifying the original ECU source code

- In many cases can use a free ATI GNU compiler

- Purchase only the functionality needed

- Cost effective for fleet and durability testing of new algorithms

- OnTarget is ideal for the prototyping and testing of new closed-loop functions and Function A/Function B comparison testing

- Both the base strategy and the bypass model are calibratable simultaneously

- Harnesses the modeling abilities of Simulink combined with the calibration support of VISION

Model Browser

ATI's Model Browser provides a sophisticated user interface of Simulink models from within VISION software to enhance OnTarget or xPC Target calibration and data acquisition functionality. The Model Browser Screen Object provides a real-time view of the Simulink model in terms of data and control flow rather than the typical list of numbers and enables graphical measurement and calibration of the model during development and testing.

Key Features:

- View and calibrate the function of the entire system from VISION including the ECU, the new model (internal to the ECU via OnTarget or external via the xPC Target Software), and data acquisition devices may be viewed and calibrated

- Show live data on the signal lines and parameter values on the blocks displayed in the model

- Add constants, curves, maps, and other calibratable data items from the blocks to the familiar calibration screen objects of VISION

- Navigate the model by clicking on subsystems through the model tree view or through the model subsystem views (similar to Simulink)

- No need for the MathWorks® MATLAB® or Simulink® softwares

Model Based Calibration

Key Features:

- Integration to existing models within VISION by linking the model running within the Simulink® environment to the VISION computer.

- Post model integration common device interface. The distinction between this virtual device and all other physical devices is transparent to VISION.

- Powerful display of signals and calibration parameters including user configurable strip charts, recorders, lookups, dials and gauges are available.

- Users can view models in VISION along with dynamic data overlays with the optional VISION Browser for Simulink® Models Toolkit.

Requirements

| Computer | Window 7 (32-bit or 64-bit) or Window 10 (32-bit or 64-bit) , Minimum 1 GHz processor and 1 GB of RAM. |

| Calibration Interface | A supported ECU calibration tool interface is required, such as a memory emulator, a serial interface or network communication interface (CCP) |

| Information | ECU Base Strategy (or ECU executable and description files) which is comprised of HEX and ASAP2 files for the ECU under test. The strategy MAP file is helpful but not required. |

| Functionality | The ability to re-flash the ECU including the recalculation of any checksums on the code and calibration memory space. |

| Memory | Unused Flash and RAM memory (including code, calibration and RAM areas) to accommodate new code and/or variables (note: typical ECUs have spare memory; ATI Support can help determine initial settings for your application at no cost) |

| Additional Software |

|

MathWorks Compatibility Chart

ATI Software License Models:

- STD - Single node (PC) locked license (one serial number on one device), 1st 12 months Dynamic Maintenance, updates and 24/7 technical support included. (Subsequent Dynamic Maintenance every 12 months).

- MUL - Multiple node (PC) locked license (one serial number on a specified number of devices). Same billing model as

- STD license's - Floating license tied to a physical USB key enabling multiple user access (not simultaneously). Same billing model as STD license.

- SVR - Server based license for large teams of users. Allows for the running of multiple instances in remote console sessions on the single server. Same billing model as STD license.

SUB - Optional Monthly subscription license – pay as you go per month – inclusive of dynamic maintenance and 24/7 technical support. Available for all the above license types.

Software PC Requirements

No-Hooks Rapid Prototyping Software

The requirements of No-Hooks/ OnTarget Rapid Prototyping Software are:

- A development tool interface to the electronic control unit (such as a memory emulator, a serial interface or network communication interface (CCP).

- The ability to re-flash the ECU including the recalculation of any checksums on the code and the calibration space.

- Available memory space in the ECU (Code, Calibration, and RAM).

- The software memory image (hex, s-record, binary or other) and data-item description file (ASAP2 file or other).

| Note: These are the traditional files supplied for calibration of an ECU. |

- Appropriate processing power on the ECU capable of handling the additional functionality.

- ATI's VISION Calibration and Data Acquisition Software

- VISION Microprocessor-specific No-Hooks Toolkit and if using OnTarget, Microprocessor- specific OnTarget Toolkit

- A processor supported by No-Hooks/OnTarget.

- Optional: ATI Model Browser Toolkit for Simulink Models (for more information, see the Model Browser section.)

Important: No-Hooks/OnTarget is microprocessor specific. See the No-Hooks/OnTarget Supported Processor section for details. If you have an interest in No-Hooks for any of the processor not listed, please contact ATI at (248) 848-9200 to discuss your application in detail. |

| Note: No-Hooks/OnTarget Rapid Prototyping was designed to work with VISION Calibration and Data Acquisition Software. No-Hooks/OnTarget does not work directly with other calibration tools, however an additional toolkit can be purchased to export a modified A2L and Hex file for use with other calibration tools. Please note that advanced features such as the Model Browser, real-time strip chart recorders and VISION API scripting will not be available with these other tools. |

All specifications are subject to change without notice.