Understanding ATI Dynamic Overlay Support in ECU Development

What is Dynamic Overlay support?

Dynamic Overlay support in a microcontroller allows flash sectors to be remapped to RAM. Moving a flash sector containing calibration parameters to RAM allows VISION to make calibration changes while the control system is operating. A key benefit to this approach is that it does not require microcontroller software to support it, however it does require that the microcontroller supports Dynamic Overlay.

How It Works

- Partitioning Memory: Dividing Flash memory into fixed regions that can be remapped to RAM dynamically.

- Overlay Management: This is a dynamic process that keeps track of what memory is currently remapped and if new regions need to be remapped.

- Optimized Resource Usage: The A9 only re-maps what is needed for the current calibration session.

- Transparent: The A9 manages the overlay process in the background without the need for user intervention.

- Cost Efficiency: Saves time and increases the efficiency of the calibration process.

Application in A9 Serial Interface

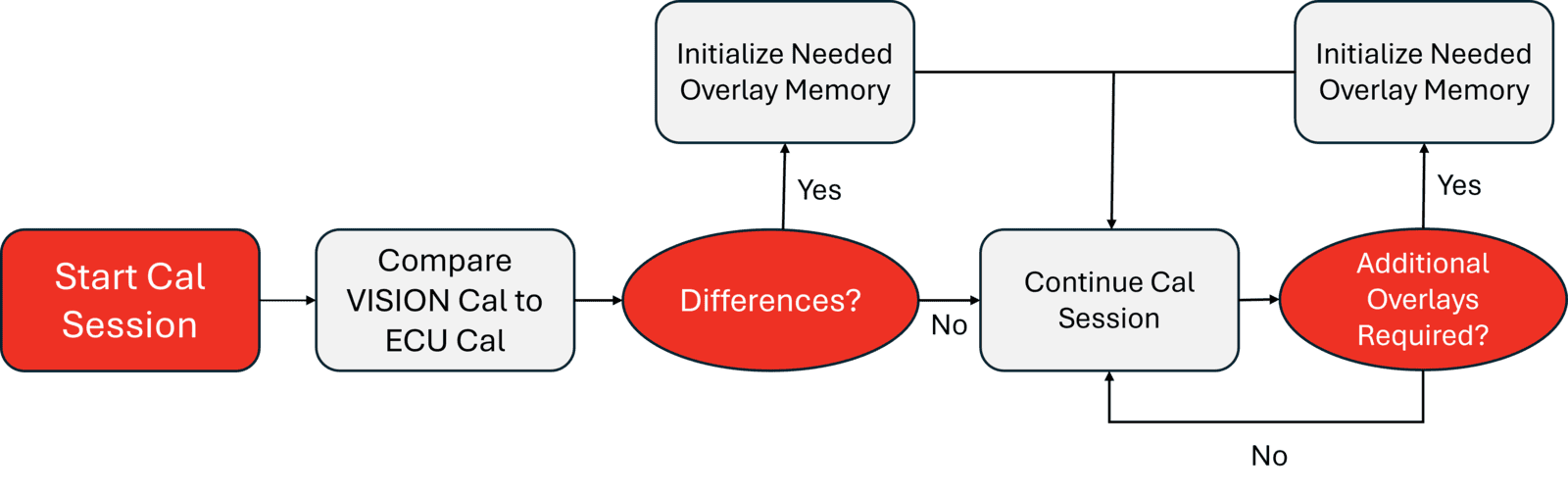

This is a high-level flowchart of the Dynamic Overlay management with the A9 and ATI VISION.

The system consistently monitors requested calibration changes to determine if additional overlays are needed. It is possible that the address space for the requested calibration items exceeds the size of the available Overlay RAM. When this occurs, the user is prompted to Flash the ECU. All available Overlay RAM is freed up once the flash is completed.

Conclusion

Dynamic Overlay support is a key feature to reduce the time needed to calibrate an embedded control system. Having the process operate transparently in the background frees up the calibrator to concentrate on their tasks.