Logging, Analyzing, and Replaying CAN Data

Record and Playback with CANLab

Capturing CAN Traffic: Building a Reliable Log

ASCII Message Logs – Common format for raw message logs that are supported by popular tools

CSV – For external post-processing and visualization of decoded CAN signals workflows

ATI native formats – For high-speed playback and detailed analysis within CANLab

The result is a clean, well-structured log file that forms the foundation for analysis, troubleshooting, and repeatable testing.

Analyzing and Visualizing Recorded Data

Once the messages are captured, CANLab can transform the raw hexadecimal frames into meaningful engineering signals using a CAN database (.dbc).

Key analysis tools in CANLab include:

Time-based plots – Overlay and compare signal behaviors across time

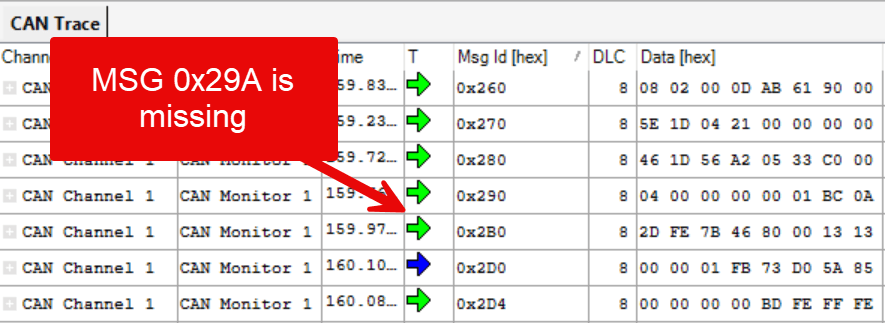

Message and frequency statistics – Detect missing, delayed, or jittery messages (see image at right)

Search and filter tools – Isolate activity from specific ECUs or subsystems

Multi-log comparison – Load and review multiple log files side by side to evaluate changes between tests or calibration updates

This data-driven analysis enables engineers to verify fixes, pinpoint faults, and understand system behavior under different operating conditions.

Replaying CAN Data: Record and Playback Testing

CANLab’s record and playback functionality allows engineers to reproduce captured network activity as though it were occurring live. This bridges the gap between on-vehicle testing and bench validation by enabling recorded traffic to be replayed in controlled conditions.

Common use cases include:

Regression testing – Replay known-good traffic to confirm consistent ECU behavior after software or calibration changes

ECU simulation – Emulate a missing ECU or subsystem by replaying its messages, enabling dependent systems to be tested in isolation

System validation – Recreate complex network conditions to confirm timing integrity and fault tolerance

CANLab offers timing control, looping, and synchronization features (as described in its technical documentation), ensuring accurate and repeatable playback for confident testing results.

Exporting and Sharing CAN Data

Collaboration often requires sharing data in formats compatible with other tools or teams. CANLab provides flexible export options such as:

CSV – Enable spreadsheet-based analysis or import into data visualization tools

ASCII Message Logs – Raw CAN Message traffic

MDF3 Message Logs – Preserve full functionality within CANLab and VISION

These export options streamline communication between teams and testing environments, supporting internal development as well as supplier validation.

Real-World Applications

Regression Testing

Teams can identify unintended software changes by replaying previously captured data. Deviations in timing, signal response, or message behavior reveal regressions before production release.

ECU Simulation

When certain vehicle components aren’t available, CANLab can substitute by replaying their recorded traffic. This allows subsystem testing and integration validation without requiring every physical ECU—saving both time and resources during development.

Wrapping Up

Logging, analyzing, and replaying CAN data fundamentally changes how engineers test, debug, and validate vehicle systems. ATI’s CANLab empowers teams to capture what happens on the network and reproduce it with precision. From real-time logging to replay and visualization, CANLab turns CAN data into actionable engineering insight.

In the next part of our CAN Bus Blog Series, we’ll move beyond the base protocol and explore Higher-Layer Protocols: CANopen, J1939, and UDS—covering how CANLab supports these standards, how structured data like SPNs and service requests are decoded, and how they’re applied across heavy-duty, medical, and robotics applications. Stay tuned as we continue uncovering the layers of modern vehicle communication.